Product Features

Following are some highlights of this versatile machine.

- MAIN FRAME:- Is fabricated by M.S plates, and all other components viz, Motor, Gear Box, Electrical Panel Box and Brake, etc. are fitted to it in such a way, as to make access easy to each, without disturbing others

- ROPE DRUM:- Is Made out of seamless pipe, of sufficient thickness. The grooves are very accurately machined on it, which ensures proper sitting of wire rope in it. It is supported on Ball Bearings, by high-tensile steel adaptors.

- ROPE GUIDE:- It prevents the rope from overlapping on drum, and guides it accurately to the grooves. It is designed, so as to enable easy removal, for maintenance purposes. It also guards against slackening of the rope on the drum.

- GEAR BOX: A specially designed gear box is attached to the frame. It transmits power from motor to the drum, with the greatest possible mechanical advantage. The Gears are of special Alloy Steel. They are precisely machined, hardened, and tempered, or longer life, with smooth and noiseless running.

- SUPPLY VOLTAGE:- 440V.3 phase, 50c/s.

- CONTROL VOLTAGE:- 24V (for operator safety).

- IMPROVEMENT:- Our design personnel, continuously make efforts for improvement, And we reserve the right to affect and change, if found necessary without any notice.

- TESTING:- The hoist components are subjected to strict quality control procedures. And the hoist is finally tested to 25% overload.

- GUARANTEE:– A guarantee is provided, for the repair and replacement – F.O.R. – Mumbai, of any part, which proves defective, in material or workmanship, within 1 year of sale.

- HOOKS:- The Alloy Steel, forged, heavy duty, hook, is supported on thrust bearing, in the bottom block frame, which is robustly fabricated.

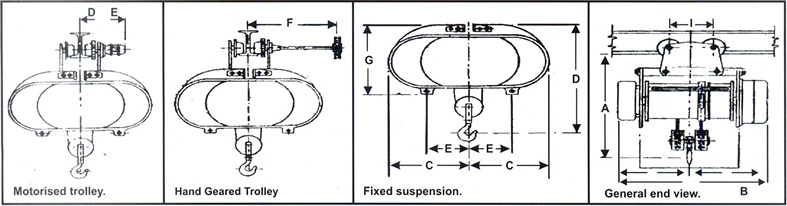

- TROLLEY:- The trolley can be adjusted to different beam sizes. The trolley wheels are made of steel, having a perfect Curve to enable running, with minimum friction on beam.

- BRAKE:- Specially designed for hoist application, fail safe, electromagnetic disc type brake, ensures complete safety at any hoisting position. These Brakes are self adjusting, for wear.

- ELECTRIC MOTOR:- Special Hoist duty motor used, with class B insulation. Thses are suitable for more than 100 starts and stops per hour.

- BUILT IN SAFETY MEASURES:-(A) Limit switches provided, to stop the hoist immediately, as soon as the maximum hoisiting or lowering limit is reached. Thus preventing any mechanical damage to the equipment. (B) A Bi-Metal relay, protects the equipment, against single phasing of supply voltage.

- ELECTRICAL CONTROL PANEL:- This is enclosed in a box. Which is weather and dust-proof. It houses the best and most reliable quality components.

- PENDANT PUSH BUTTON STATION:- Suitably designed to, reduce operator fatigue. It is robust, heavy-duty, dust and vermin-proof, suspended by a strain cable, to take its full load.